Adhesives are an essential component of making a successful label.

However, it can be challenging to determine which one makes the most sense for your product. There are many different factors to consider, such as what the label will be going on, how long it needs to stay there, and what types of conditions the label will go through. Is the label going on a product that needs to be refrigerated? Will it be exposed to heat or chemicals? These types of questions will help determine which type of adhesive will work the best.

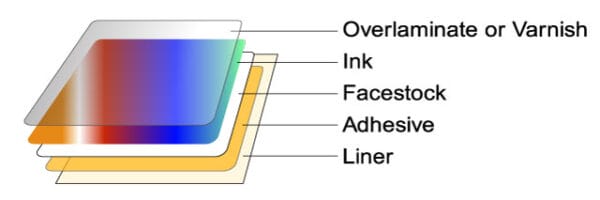

The diagram above shows the basic components of a label. The topcoat is a physical surface coating that is applied to increase ink adhesion or modify gloss. The ink layer refers to the label graphics. The facestock is the film or paper that the ink is printed on. The adhesive is a coating used to bond the label facestock to the application surface, and the liner supports the product until use.

Adhesive Types

The first step in choosing an adhesive is to determine what type you need. There are three main types of adhesives. Permanent, Removable, and Repositionable.

- Permanent

- Removable

- Repositionable

Basic Properties

Once you decide which type of adhesive is needed, take a look at some of the additional properties that determine an adhesive’s performance.

- Tack

- Ultimate Adhesion

- Shear

- Service Temperature Range

- Minimum Application Temperature

It can be challenging deciding what adhesion type is needed for a label, but if you understand what the label will be used for and what situations it will encounter, the experts at Whitlam Group can help you decide what’s best and perform tests to ensure that the solution is effective.

Click on the link to read more about Adhesives and the different types/properties.

Leave a Reply