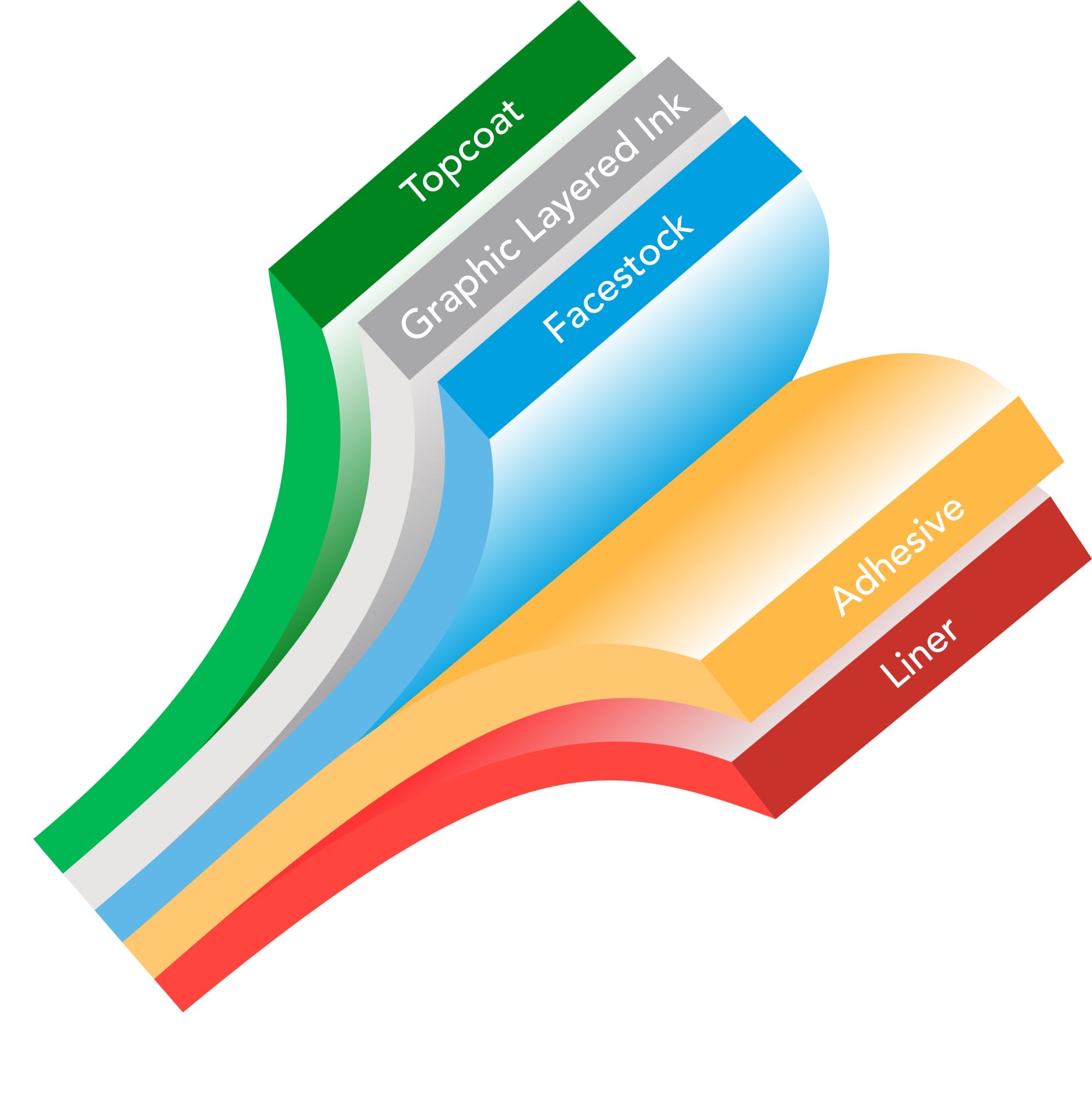

A typical label consists of a topcoat, face stock, ink, adhesive, and a liner.

TOPCOAT

A physical surface coating is applied to promote or increase ink adhesion with conventional and digital print technologies or to modify gloss.

GRAPHIC LAYERED INK

Ink is laid down between the topcoat and the face stock.

Face Stock

Film or other specialty paper, fabric, or membrane to which the topcoat and adhesive are anchored. Carries graphics to the application surface. Functions as a protective laminate. Provides a barrier to moisture or vapor. Functions as a spacer material in a layered construction.

ADHESIVE

A pressure-sensitive or heat-activated coating is used to bond the film to the application surface.

LINER

Supports the product through manufacturing and life of use. Protects adhesive until it is applied to the end user’s surface.

Learn more about our Label Construction process: Different Label Characteristics