Custom Functional Components Solve Unique Problems

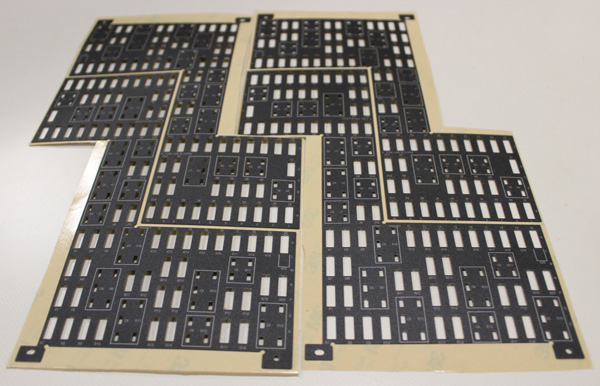

Functional die-cut component solutions are custom engineered to your specifications to improve assembly operations and reduce contamination, damage, and scrap all while generating cost savings. Functional components, for example, could be a solution that allows you to use a die-cut component to replace a heavier, more expensive gasket, bushing, or cap.

By engineering part-specific, functional, die-cut labels, the part can be protected from debris and contamination throughout shipping and installation. The die-cut label will also provide assistance with error-proofing and process control during assembly.

Functional Die-Cut Components

Protective die-cut components are made from a variety of films that feature a removable adhesive, allowing them to be easily applied and removed without leaving residue. These components are designed to shield surfaces from scratches, dust, and other environmental factors, enhancing durability and maintaining the aesthetic appeal of the items they protect. The films can vary in thickness, transparency, and adhesive strength, uniquely designed to meet your specific needs.

Product Options

- Functional die-cut components

- Protective films, covers, and masks

- Paint mask

- Shatter protection

- Electrical or thermal management

- Fastening

- Noise control/sound dampening

- Double-sided adhesive parts for the assembly of housing components

Technical Options

- Application to metal, painted metal, plastic, or glass

- Designed and die-cut to fit your specifications and application requirements

- Protects surfaces during assembly or shipping

- Variety of adhesive solutions; easy repositionability

- Removes without leaving a residue

- Withstands extreme temperatures

- Custom print for identification and/or machine readability

Protective Film Solutions

Functional protective film solutions can simplify and enhance the efficiency of many manufacturing processes.

In many engineering applications, protective film solutions are now doing jobs that previously required entire assembly components. These multifaceted products often combine several functionalities into a single element.

Whitlam Group supplies protective film solutions to guard a wide variety of surfaces, including freshly painted components, throughout your process and all the way to the dealer. These protective films remove cleanly and easily, even after extended exposure to the elements.

Therefore, you can simplify your various production processes by opting for multi-functional films. Protective films are the best choice for protecting your product from defects.

Protective Film Features

- Abrasion-resistant

- Chemical-resistant

- Scratch-resistant

- UV-resistant

Protective Component Solutions

- Adhesive-free solutions

- Removable adhesive solutions

- Permanent part protection

- Surface protection

- Paint mask

- Hole covers

- Shatter protection

Protective Film Adhesives

Our protective film adhesives solutions offer a wide variety of permanent and removable adhesives. These include rubber and acrylic surface protection films that allow for a residue-free surface. We can engineer and manufacture custom surface protection films for many uses.