Flexographic Printing

Whitlam Group is always on the lookout for technology that both streamlines our processes here and cuts down on costs. That’s why we keep an eye out for and investigate each new advancement as it presents itself. If we fall behind, then our competitors have a good chance of taking the lead away from us. One the advancements we’ve been watching has to do with Flexographic printing. It hasn’t always been as popular with industrial printers as it is today, but the advances in anilox technology has changed that.

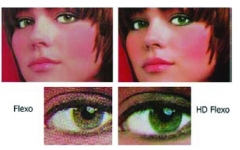

Anilox is a method used to provide the correct amount of ink to flexo printing plates. The evolution of this technology, and flexo printing in general, has allowed those in the printing industry to move from lower-quality printing to printing high definition images. The industry has moved away from the gravure over the past decade to a 10-or-more color flexographic process. Because new packaging requires high quality images, HD flexo printing has not only become the industry norm, but the expectation.

And as with any new technologies, there is always an adjustment period. As Labels and Labeling points out, “… moving printers from 100lpi to 150lpi or even 200lpi, doesn’t mean the quality will be better, it could actually cause more problems. Do printers today really understand the benefits and challenges that this superior plate and higher plate screen technology gives them?”

At Whitlam, we do understand these benefits and challenges and are quick to adopt new technologies.

Another benefit of using HD flexo printing is that it makes hard-to-print designs and colors much easier to utilize. For example, prior to new anilox technology, it was most difficult to print flesh tones, but now with the ability to print finer dots, that’s no longer an issue. And what’s even better is the fact that flexographic printing allows you to print on nearly any surface. This diverse range of substrates combined with HD printing doesn’t just make your product’s labeling better, but helps your company be more successful. By offering your product the ability to print in higher quality, you’ll be able to create labels that not only attract new customers, but keep the ones you already have.

Flexographic printing is also a very cost-effective way to have your company’s printing needs met. One of the reasons it’s so cost-effective is that many flexo printers, while using a lot of ink, are able to recycle most of the unused ink and wash waters. So if you’re interested in investing in a relatively low-cost way to improve the overall look and feel of your product, contact Whitlam Group today!

One response to “New Flexographic Technology Allows For HD Printing”

Posted by chad

Flexographic printing like all other printing process is becoming more and more technologically advanced. Who would have thought HD Flexo printing?

Posted on December 11, 2012 at 8:47 AM