Whitlam Group’sLabel Printing Capabilities

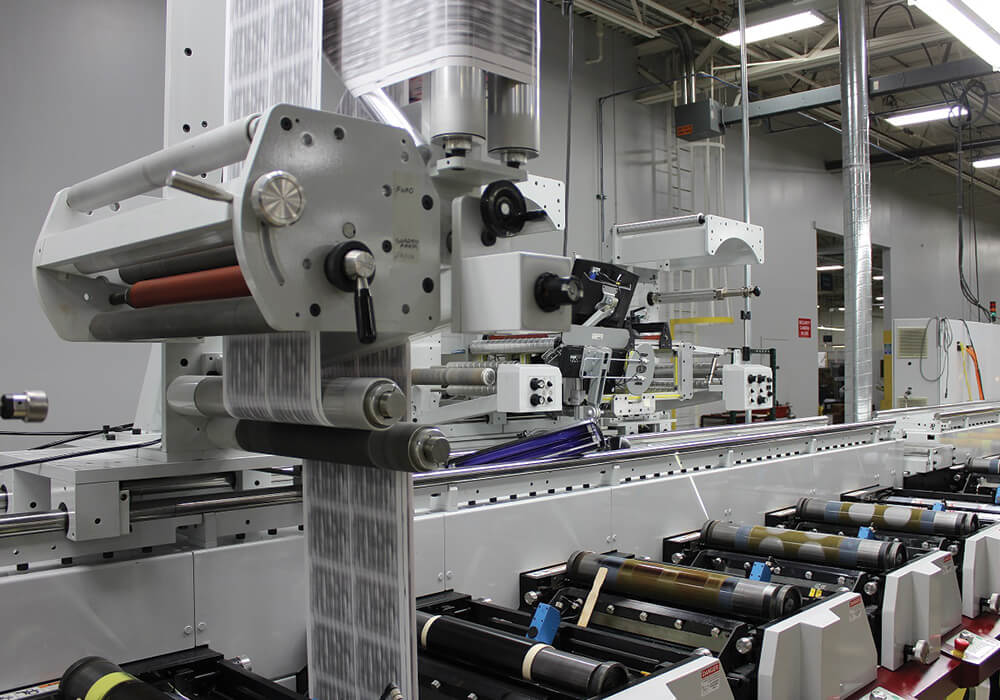

Flexographic Printing

Our flexographic presses can print up to 17” wide and can handle up to 12 colors in a single pass, delivering consistent quality. These presses can be used to print on a variety of substrates including paper, film, and metallic films. Our flexographic presses can be combined with in-line processes such as rotary screen and foil, allowing for highly customizable, cost-effective solutions.

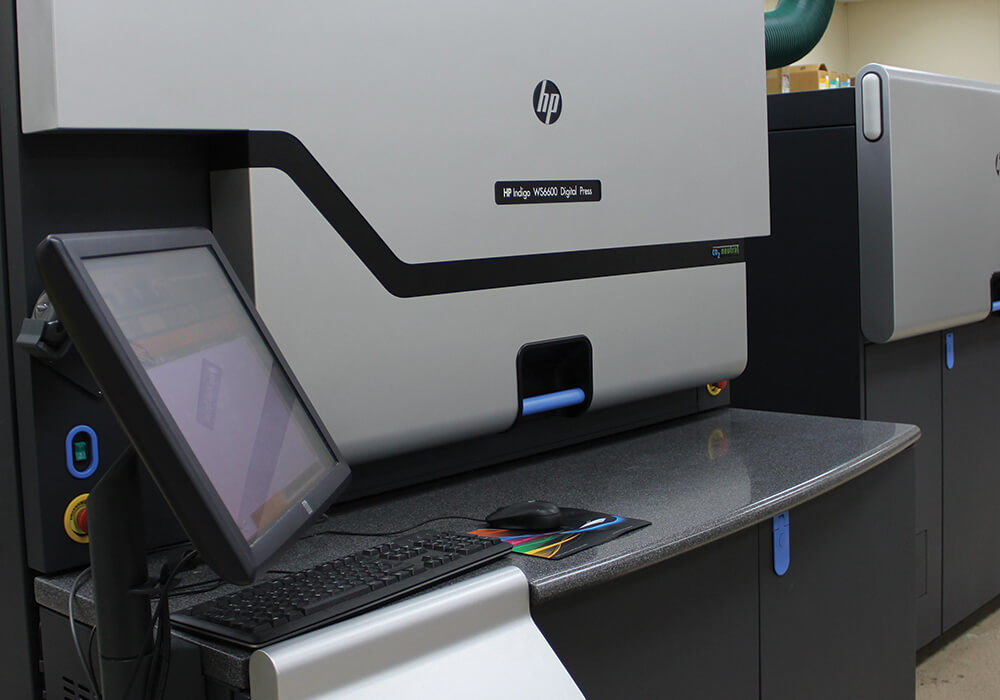

Digital Printing

Our digital presses offer a cost-effective solution for short runs and high quality jobs by using efficient change-over capabilities. Digital printing can be combined with other offline processes, such as foil stamping, to obtain special effects on a variety of substrates.

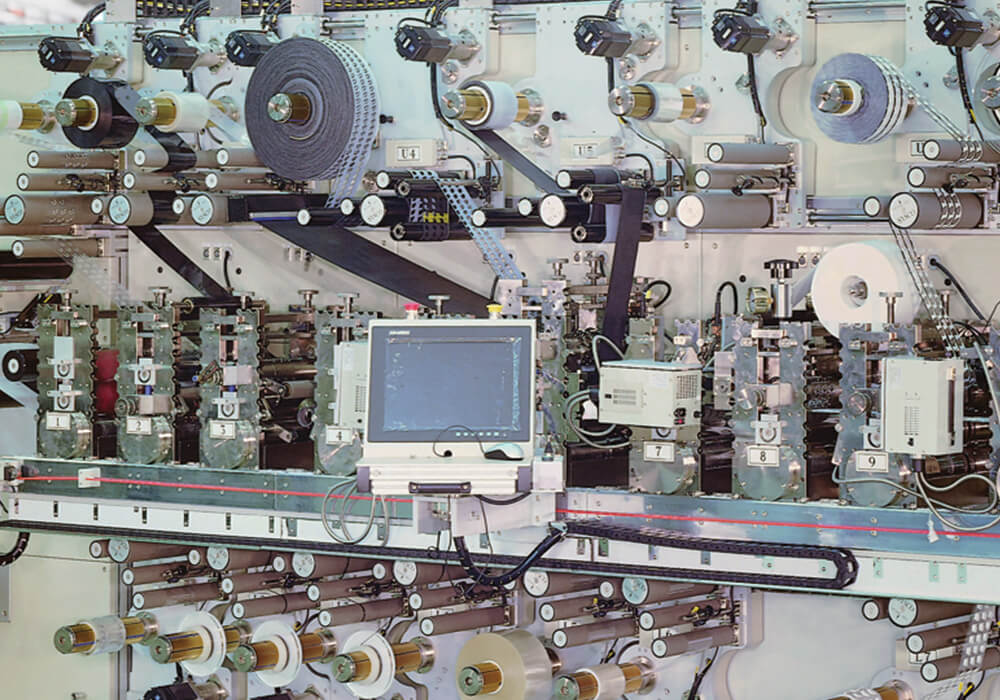

Custom Die-Cut Converting

Our team at Whitlam Group specializes in design, and custom conversion to create a product to meet your needs. This could include solving a problem, providing efficiency gains, or reducing costs. Our state-of-the-art equipment allows Whitlam to accommodate some of the tightest tolerances in the industry, down to ± .1mm (material dependent).

Printing Techniques

We can engineer your custom label solution with a variety of different techniques:

- Personalization

- Barcodes & Variable Data

- Hot & Cold Foiling

- Embossing Peel & Reveal

- Extended Content

- Direct Thermal Printing

- Thermal Transfer Printing

- Security/Brand