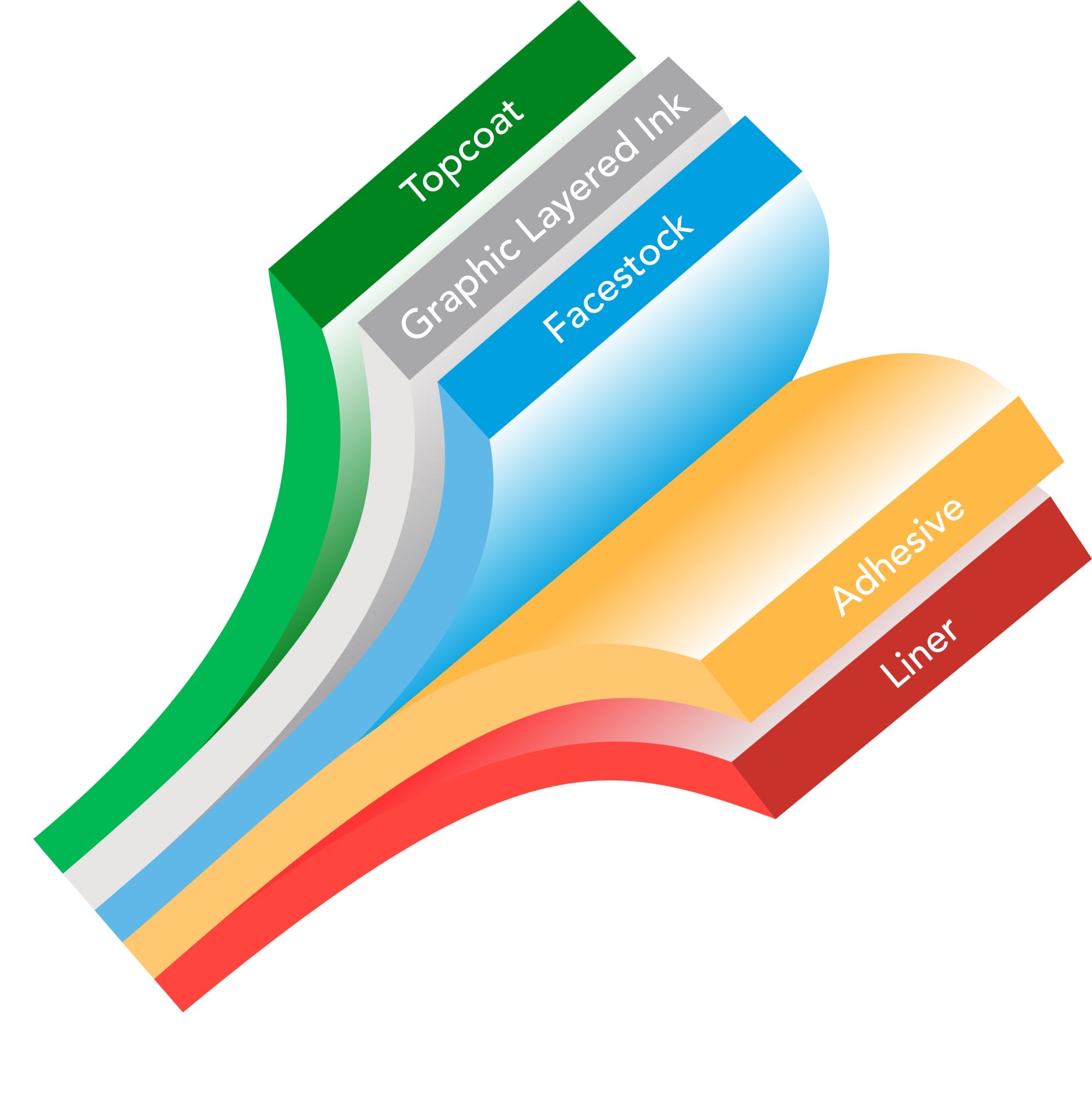

A typical label consists of a topcoat, face stock, ink, adhesive, and a liner.

TOPCOAT

A physical surface coating is applied to promote or increase ink adhesion with conventional and digital print technologies or to modify gloss.

GRAPHIC LAYERED INK

Ink is laid down between the topcoat and the face stock.

Face Stock

Film or other specialty paper, fabric, or membrane to which the topcoat and adhesive are anchored. Carries graphics to the application surface. Functions as a protective laminate. Provides a barrier to moisture or vapor. Functions as a spacer material in a layered construction.

ADHESIVE

A pressure-sensitive or heat-activated coating is used to bond the film to the application surface.

LINER

Supports the product through manufacturing and life of use. Protects adhesive until it is applied to the end user’s surface.

Learn more about our Label Construction process: Different Label Characteristics

What Is Label Construction?

Label construction is the combination of materials that make up a pressure-sensitive label. This typically includes a liner, adhesive, face stock, and sometimes a topcoat or laminate. Each component affects how the label adheres, prints, and withstands environmental conditions.

What is Face Stock in a Label?

Face stock is the top layer of a label that carries the printed information. It can be made from paper, film, or other specialty materials. The type of face stock selected impacts everything from print quality to durability and resistance to chemicals, abrasion, or UV exposure.

What is a Face Stock Label?

A face stock label refers to any label where the face stock—the printable surface—is specifically selected to meet performance needs such as flexibility, clarity, strength, or resistance. Choosing the right face stock label is essential for applications in automotive, industrial, medical, or consumer packaging.

What is a Label Topcoat?

A label topcoat is a clear coating applied to the face stock during the manufacturing process. It enhances printability, improves ink adhesion, and adds protection against environmental factors like moisture, sunlight, and abrasion. Labels exposed to harsh conditions or printed using digital or thermal transfer methods often require a topcoat for