What Are Engraving Plates?

Engraving plates are metal plates with designs, logos, or text etched into their surface. They are typically used for signage and identification, offering durability and a professional appearance for long-term use. Engraving plates are used in several industries, but alternatives such as labels are also worth considering if your company is looking for a less costly process.

Making Engraved Name Plates: The Process

Engraved name plates are used in the automotive and industrial industries. Some substrates that are used for engraved plates are aluminum, brass, polycarbonate, stainless steel and more.

Etching and mechanical engraving are processes used when creating engraved name plates. Mechanical engraving uses a high-speed rotary cutting tool to cut into the surface of the name plate. After the engraving process an enamel paint is used to fill in the engraved areas.

Etching uses acid resistant coating in its process to burn away the areas that are engraved. Once the etching process is completed then an enamel paint is used to seal and cure the name plate. The plate is then soaked, cleaned and a clear coat-lacquered is applied for extra protection. This process is used to meet certain requirements such as depth of letters into the surface of the name plate.

Alternative Solutions: Labels Vs Engraved Nameplates

All the different processes and special tools used when created an engraved nameplate can be very costly. When using the etching process, the chemicals used can be harmful to the environment.

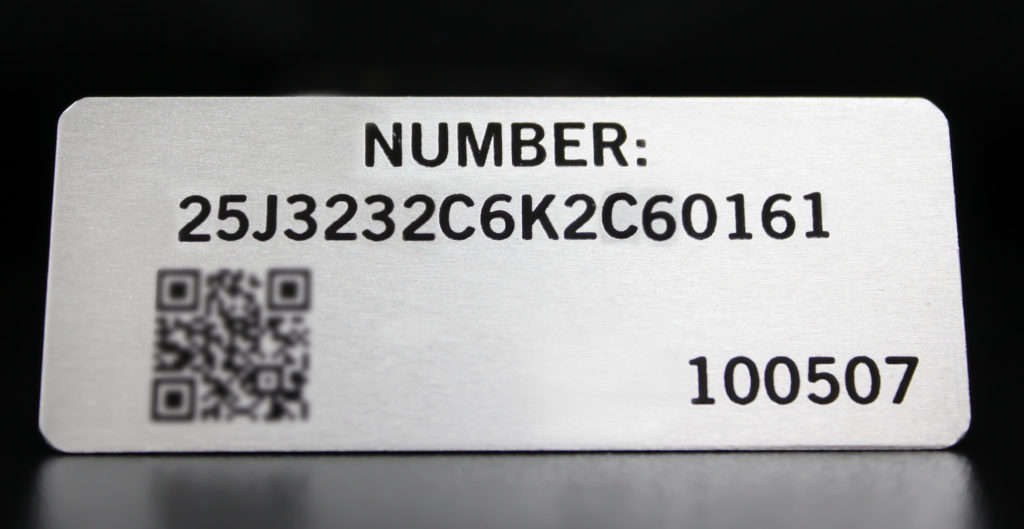

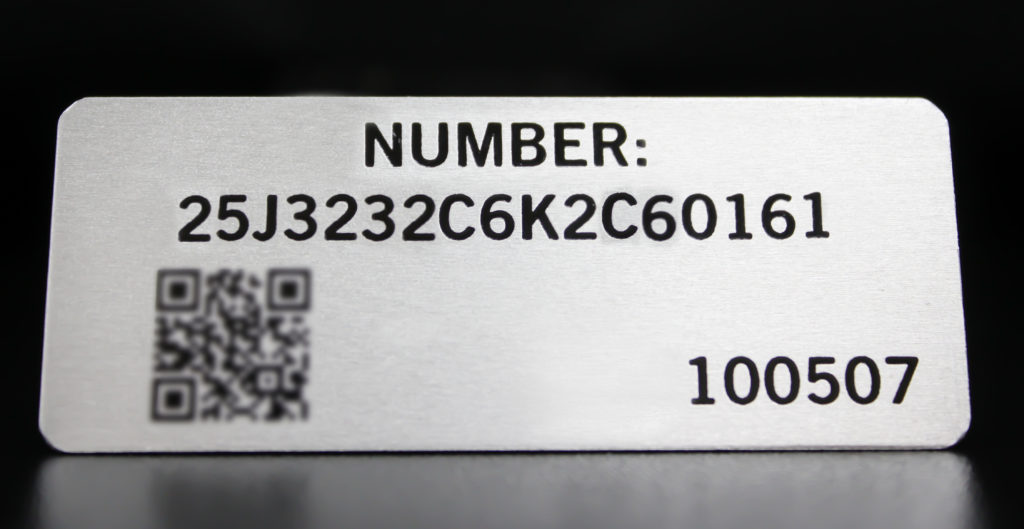

Labels can be substituted for all of these processes as long as there is not any depth requirements. Label substrates can be extremely durable and more affordable. Label substrates can be less costly then the tooling or chemicals used in the mechanical engraving and etching processes.

Using a label may open the door for more options for brand security. Label specifications can be added to make the label self-destructive or include other security features. Some of these security features may not be achievable from the engraving processes.

Labels can be placed on any surface. A metal plate may still be used for your process but instead of having the plate engraved you can place a label on the plate. Foam adhesives that are used to attach name plates to desired surfaces can be used with labels as well.

Choosing a label over engraving may allow you to be more creative in your design of the label as well. Some of the more detail logos or designs that you would like to include on your name plate might not be achievable with etching and mechanical engraving but will be achievable with the design of a label.

Whitlam Group: Brand Security Experts

Whitlam Group specializes in labels, tags and packaging. We have a state-of-the-art laboratory that allows us to test substrates to meet requirements. Some of our lab work includes abrasion, fluid immersion, heat aging/resistance, peel strength, thermal cycle and adhesion. Conforming to requirements is one of many standards that Whitlam Group abides by.

Whitlam Group also specializes in brand security. We understand the importance of protecting your brand and we aim to develop the highest possible level of security with optimum costs. Some ways we achieve this is threw tamper evident labels, authentication labels and trace securitylabeling solutions.

If you would like more information about how we can find a better solution for you, please contact us at 800-755-2235 or click here to send us a message of how we can help you.