Recognizing Fire Risks: The Flammable Liquid Hazard Symbol

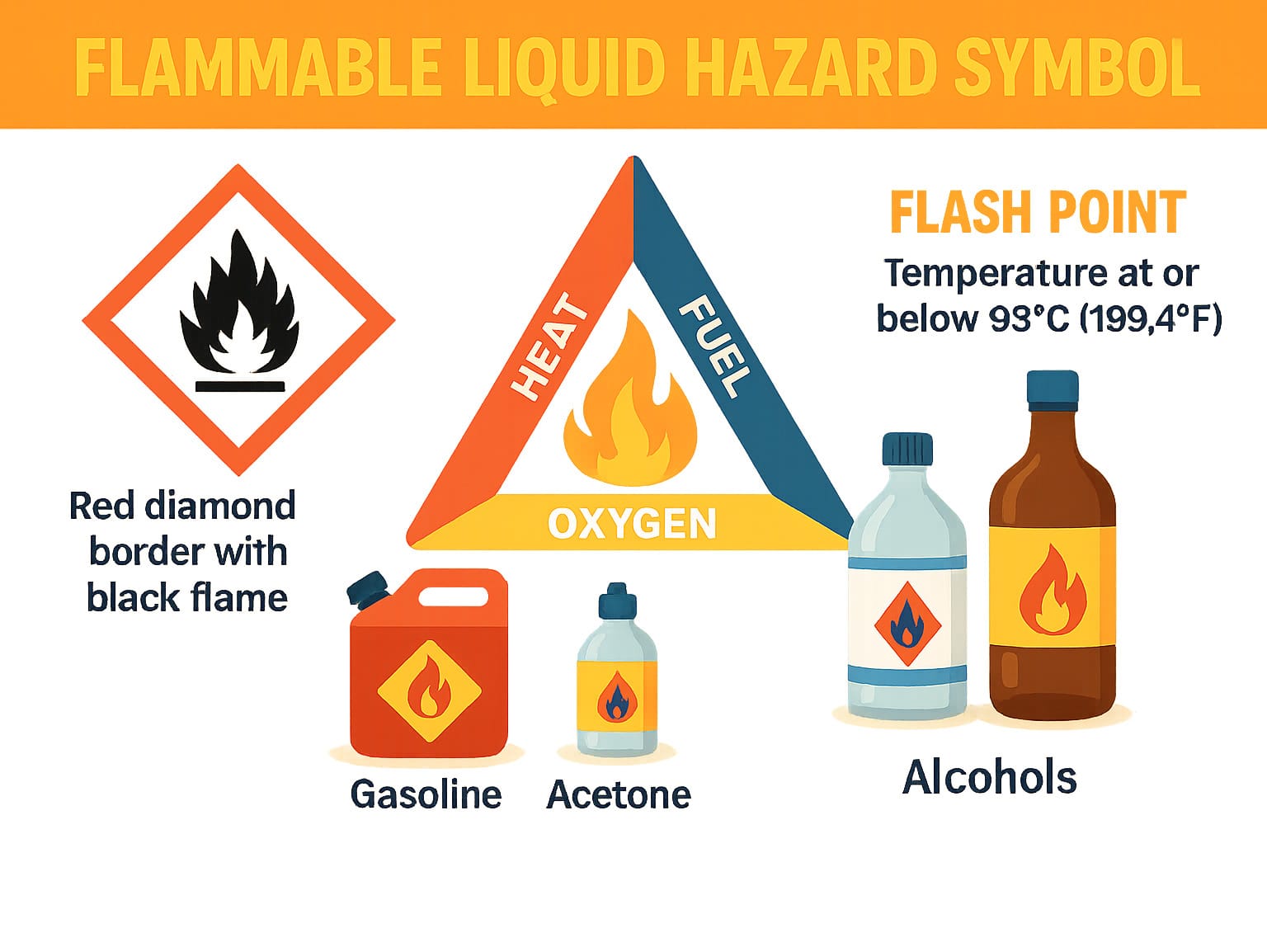

The flammable liquid hazard symbol is a red diamond containing a black flame icon on a white background. This universal warning sign alerts you to liquids easily catching fire when exposed to an ignition source.

Quick Reference: Flammable Liquid Hazard Symbol

- Appearance: Red diamond border with a black flame on a white background

- Meaning: Material can ignite easily and burn rapidly

- Found on: Chemical containers, transport vehicles, storage areas, safety data sheets

- Regulatory systems: GHS, OSHA, DOT (Class 3), NFPA

- Flash point definition: Temperature at or below 93°C (199.4°F)

This symbol is part of the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals, which was adopted by OSHA in 2016. It’s one of nine standardized pictograms designed to quickly communicate hazards without relying on language.

Understanding this symbol isn’t just about regulatory compliance but safety. When you spot the flame pictogram, you’re warned that special handling, storage, and emergency procedures are necessary. The materials marked with this symbol can ignite at relatively low temperatures, and their vapors can travel to distant ignition sources, potentially causing flashback fires.

“Hazard symbols have come a long way from the rudimentary drawings used to designate poison in the early 1800s,” notes the Chemical Safety Board. Today’s standardized system ensures everyone from warehouse workers to emergency responders can immediately recognize potential dangers.

Why This Guide Matters

Recognizing the flammable liquid hazard symbol is essential if you work with chemicals in any capacity, whether in manufacturing, transportation, laboratory settings, or even retail. This guide addresses the common search intent for quick, reliable identification of hazard symbols in the workplace.

Proper employee training on hazard communication isn’t just a nice-to-have; OSHA regulations mandate it. Companies that fail to properly train employees on hazard recognition face significant penalties, not to mention the potential for serious workplace accidents.

Understanding the Flammable Liquid Hazard Symbol

When it comes to workplace safety, recognizing the flammable liquid hazard symbol is crucial. This important warning sign appears across several regulatory systems, though you might notice slight variations depending on where you encounter it:

- GHS (Globally Harmonized System): The standard red diamond border with a black flame on a white background

- OSHA HCS (Hazard Communication Standard): Follows the GHS pictogram standards

- DOT Class 3: A red diamond featuring the flame symbol plus the number “3”

- NFPA 704: Found in the red quadrant of the “diamond” with a number (0-4) showing how severe the hazard is

While each system has its own specific purpose, they all share a common goal: to quickly alert you to materials that can easily catch fire and spread rapidly.

What the Flammable Liquid Hazard Symbol Looks Like

The standard GHS flammable liquid hazard symbol is designed to be instantly recognizable. It features:

- A red diamond-shaped border that catches the eye

- A clean white background for contrast

- A bold, black stylized flame icon

- The flame rising upward from the bottom of the pictogram

OSHA regulations are quite specific about how this symbol should appear. The pictogram must have a square red border set at a point (creating the diamond shape). Interestingly, each symbol can appear only once on a label, even when multiple hazards call for the same pictogram, a clever way to avoid visual clutter when communicating risks.

The DOT Class 3 placard looks similar for transportation purposes but includes the number “3” at the bottom of the diamond to clearly identify the hazard class. These placards aren’t small; they must measure at least 10¾ inches square, positioned as a diamond, with a solid line inner border about ½ inch from the edge to ensure visibility even at a distance.

Meaning Behind the Flammable Liquid Hazard Symbol

When you spot the flammable liquid hazard symbol, it’s telling you something specific about the material inside:

- It has a flash point at or below 93°C (199.4°F)

- It can catch fire easily when exposed to an ignition source

- It presents a serious fire and/or explosion hazard

- Its vapors might travel surprisingly far to reach ignition sources

The flash point is the lowest temperature at which a liquid gives off enough vapor to form a mixture with air that can ignite. The lower the temperature, the more dangerous the liquid is as a fire hazard.

On labels, you’ll typically see this symbol accompanied by hazard statements like “Extremely flammable liquid and vapor,” “Highly flammable liquid and vapor,” or simply “Flammable liquid and vapor.” Which statement appears depends on the specific category of flammable liquid – something we’ll explore more deeply later in this guide.

Where You’ll Find the Flammable Liquid Hazard Symbol

The flammable liquid hazard symbol shows up in many places throughout the workplace.

On chemical containers of all sizes, from tiny lab bottles to large industrial drums. This includes primary containers, secondary containers, and workplace labels that help everyone stay safe.

It appears in Safety Data Sheets (SDS) in Section 2 (Hazard Identification), providing crucial information about the risks associated with the material.

The symbol marks storage areas including cabinets, rooms, and facilities where flammable liquids are kept, creating a visual reminder of the potential dangers.

You’ll also spot it on facility doors leading to areas where flammable liquids are used or stored, providing an immediate warning before you even enter.

At Whitlam Group, we take pride in designing and producing GHS-compliant labels that incorporate all the required elements: proper pictograms, signal words, and hazard statements. Our automotive clients throughout Michigan particularly value our attention to detail, as they regularly handle various flammable substances like solvents, paints, and fuels.

Who Requires It & When

Several key regulatory agencies require the use of the flammable liquid hazard symbol:

OSHA regulation 1910.1200 places the responsibility on employers to ensure hazardous chemicals are properly labeled with pictograms, signal words, hazard statements, and precautionary statements. This isn’t optional; it’s the law.

The Globally Harmonized System (GHS) represents an international approach to hazard communication that the United States adopted through OSHA. This standardization helped create a universal “language” for chemical hazards. Chemical manufacturers and importers had to comply by June 1, 2015, while distributors had until December 1, 2015, and employers until June 1, 2016.

DOT regulations (49 CFR §172) require placarding for transportation of hazardous materials. For flammable liquids specifically, placards become mandatory for bulk shipments of 454 kg (1,001 lbs) or more, helping everyone from highway travelers to emergency personnel quickly identify potential dangers.

The EPA also requires proper identification of hazardous waste, including flammable liquids, to ensure proper handling and disposal.

It’s worth noting that while most systems now align through GHS adoption, some differences remain. For example, the environmental hazard pictogram is mandatory in many countries but remains optional in the U.S. under OSHA regulations – one of those regulatory quirks that safety professionals need to keep track of.

Practical Safety: Classification, Handling & Emergency Response

Understanding the flammable liquid hazard symbol is just the beginning of workplace safety. You need a practical grasp of how these materials are classified, proper handling techniques, and emergency response protocols to protect yourself and your colleagues. Let’s break this down into everyday knowledge you can actually use.

Safe Storage & Handling Procedures

A few key safety practices can prevent disasters when working with materials marked with the flammable liquid hazard symbol.

Always use approved flammable cabinets with self-closing doors for storage; those bright yellow cabinets aren’t just for show! Keep storage areas well-ventilated and temperatures cool (below the flash point when possible). It’s also smart to limit quantities to just what you need and keep containers tightly sealed when not in use.

When handling these materials, always check the Safety Data Sheet (SDS) first. It’s your safety instruction manual. Work in well-ventilated areas and eliminate ignition sources like open flames, hot surfaces, or static electricity. Speaking of static, proper bonding and grounding when transferring flammable liquids is crucial.

“Static charge can accumulate on flammable liquids during transfer and act as an ignition source,” warns the Canadian Centre for Occupational Health and Safety in their guide on How to Work Safely with Hazardous Products Using the “Flame” Pictogram. “Grounding and bonding are essential.”

Differentiating Similar Symbols

The flammable liquid hazard symbol is part of a family of warning signs you should recognize:

The standard Flame (Flammable) symbol warns about materials that easily catch fire, while the Flame Over Circle (Oxidizer) indicates materials that don’t burn themselves but make other materials burn better. Think oxygen tanks.

Other related symbols include the Gas Cylinder for pressurized gases and the Exploding Bomb for materials that might, well, explode. Then there’s the NFPA Diamond system, a completely different approach using a four-colored diamond with numbers to indicate various hazards.

The NFPA system rates flammability from 0 to 4, with 4 being the most dangerous (flash point below 73°F). This system helps emergency responders quickly assess a material’s multiple hazards.

Telling these symbols apart isn’t just academic; it changes how you respond to emergencies and handle materials day-to-day.

How Whitlam Group Helps

The flammable liquid hazard symbol is more than just a red diamond with a black flame; it’s a vital communication tool that could mean the difference between safety and disaster. Understanding this symbol isn’t just about recognizing a picture; it’s about comprehending the serious risks it represents and knowing how to respond appropriately.

At Whitlam Group, we’ve spent decades helping companies throughout Detroit and beyond meet their labeling challenges. When Michigan automotive manufacturers need durable, compliant hazard labels that withstand harsh shop floor conditions, they use our expertise. We take pride in creating labels that ensure your workers, transporters, and emergency responders have clear, accurate information exactly when they need it most.