steam re-moisturization and paper substrates

Many experts are starting to speak out about their love for steam re-moisturization when dealing with the numerous problems with paper substrates. Improving substrates is often overlooked, but it’s always a great idea to learn a better way to count paper-label stock to avoid substrate curls. Whitlam Group specializes in various printing capabilities, but we want to inform our friends about important information regarding steam re-moisturization.

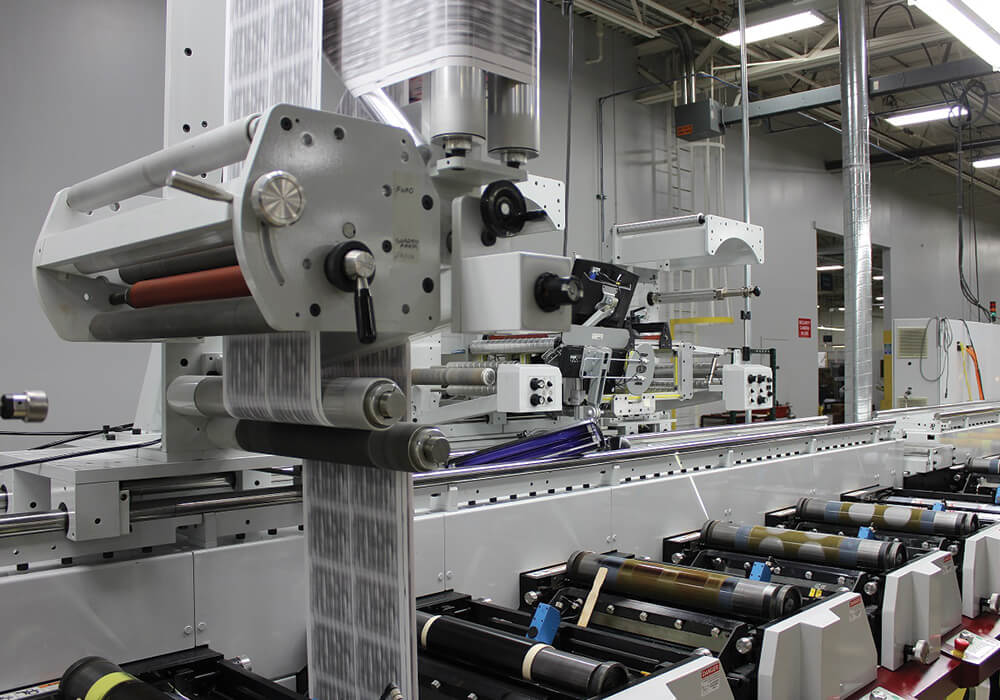

In today’s market, the consumer wants their look to be simple and have the “lay flat” look. Unfortunately, curls during the printing process can result in poor labels, jammed equipment, and the ability to slow the entire printing process. While there are numerous ways to solve the problems of curled labels, today, we’re going to focus on the most common solution: re-moisturization.

What Are Paper Substrates?

Paper substrates are the base materials for labels, packaging, and other printed products. These substrates are typically derived from wood pulp and can vary widely in quality, texture, and finish to suit different applications. Important characteristics of paper substrates include weight, thickness, smoothness, and durability. They can be coated or uncoated, with coatings providing additional properties such as gloss, resistance to moisture, or enhanced printability. Paper substrates are versatile, cost-effective, and easily customized with various printing techniques. They can also be made from renewable resources and recycled, aligning with sustainable packaging practices.

Follow these tips if you are ready to purchase a steam applicator:

- The re-moisturizer should not allow steam to seep out in any way into the atmosphere. You can avoid this problem of water dripping by using an enclosed and steamed applicator. This will safely reduce the escape of steam, and a heated exterior shell will prevent condensation.

- The re-moisturizer must provide the necessary amount of moisture for the various types of coating, the machine’s speeds, and paper basis weights. Suppliers will be responsible for showing how they could meet intended levels.

- The re-moisturizer must be fabricated with the best materials possible to guarantee maximum preservation and uptime. Steam valves must also be robust enough to make it through long years without ever being replaced.

- You should install an automatic control system into the re-moisturizer itself.