Underwriters Laboratories (UL) Labels

Underwriters Laboratories (UL) ensures products meet strict safety standards essential for manufacturers, organizations, and consumers. UL labels testify to a product’s compliance with these safety standards. This globally recognized certification entity ensures that products across various industries meet stringent safety standards. At the heart of UL’s certification process are the UL Labels. This article sheds light on their significance and the rigorous process behind their accreditation.

Underwriters Laboratories (UL) ensures products meet strict safety standards essential for manufacturers, organizations, and consumers. UL labels testify to a product’s compliance with these safety standards. This globally recognized certification entity ensures that products across various industries meet stringent safety standards. At the heart of UL’s certification process are the UL Labels. This article sheds light on their significance and the rigorous process behind their accreditation.

What are UL Labels?

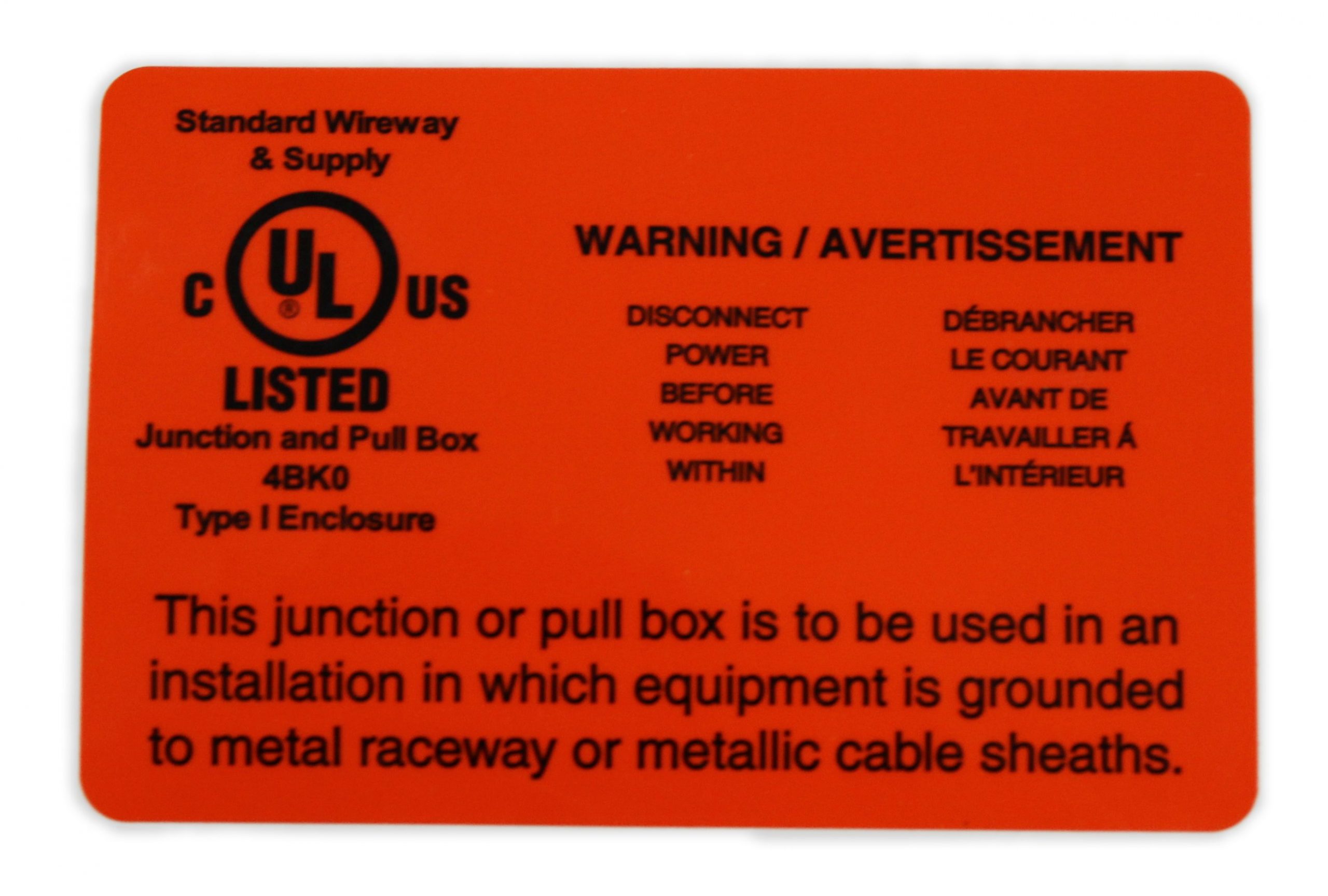

UL labels come in two primary forms: UL Listed and UL Recognized. UL-listed labels indicate that UL has tested a product and meets applicable safety standards. UL Recognized labels are used for components that may be part of a larger product or system. Both labels signify a commitment to safety and compliance but serve different purposes within the product certification ecosystem.

Importance of UL Recognition for Labels

It’s crucial for products to earn UL certification and for their labels to be UL Recognized. As a UL Authorized Label Supplier, Whitlam Group adheres to stringent guidelines to maintain this status. This includes ensuring that the labels meet the high standards set forth by UL, guaranteeing that they can withstand various conditions without degrading the safety information they carry.

UL Audit and Surveillance Testing

UL Recognition involves rigorous audits and surveillance testing. UL auditors may conduct surprise inspections at the label manufacturing facilities to ensure ongoing compliance. These labels must meet the criteria outlined in the ANSI/UL969 Standard, which encompasses a range of label categories, each with specific requirements based on the label’s intended use and environment.

Categories and Types of UL Labels

The diversity of UL labels is captured in categories such as PGDQ2, PGJI2, and others, each tailored to different labeling needs. Type R labels convey critical safety information, including hazards and installation instructions. For instance, UL 299 is dedicated to dry chemical fire extinguishers, emphasizing the labels’ role in safety communication.

UL Standards and Label Testing

Adhering to UL and IEC standards, label testing encompasses various evaluations — from weather resistance to chemical exposure. This ensures that labels remain legible and intact under adverse conditions, preserving their safety information. UL’s CTDP and DAP programs enable certified labs to conduct these tests, ensuring equivalency with UL’s rigorous testing standards.

Certification and Approval Process

The approval process for UL labels includes assigning a UL File number. This number signifies that the inks and materials used in the label’s construction meet UL’s stringent requirements. It’s a hallmark of reliability and compliance for manufacturers and consumers.

Compliance and Additional Information on Labels

Manufacturers looking to add extra information to UL Recognized labels must ensure that any additional markings, like those made with Thermal Transfer printing, use UL-approved ink ribbons. This adherence safeguards the label’s compliance and, by extension, the product’s UL certification.

Remember, Whitlam Group is a UL Authorized Label Supplier, and we must pass inspections conducted by a UL auditor. UL auditors may visit the label manufacturing facility at any time, often without prior notice, to inspect or collect UL label samples for ongoing routine surveillance testing.

UL-recognized labels must pass testing as outlined in the ANSI/UL969 Standard. Depending on the type of label, there are several different categories (PGDQ2, PGJI2, PGIM2, PGGU2, PGIS2, PGGU8, etc.). Type R labels are permanently marked with safety information such as hazards, warnings, cautions, installation instructions, and electrical ratings.

UL 299 is for dry chemical fire extinguishers. IEC standards include “Durability of Marking Requirements.” UL or a UL-certified test lab must conduct the label testing. A lab may be certified under UL’s CTDP (Client Test Data Program) and DAP (Data Acceptance Program).

The certified lab’s testing must be equivalent to that of UL’s lab testing. This testing may evaluate weathering, legibility, defacement, chemical exposure, moisture exposure, aging, adhesion, and abrasion. Once approved, the inks and materials used in that specific label construction combination are granted a UL File number.

Whitlam Group has several different UL-approved label construction files for different label applications. Working with a UL-authorized label Supplier such as Whitlam Group and using our pre-approved UL label constructions can reduce your costs and time by eliminating the need for you to conduct such testing.

Work With Whitlam Group

UL labels are symbols of safety, reliability, and compliance. Whitlam Group’s dedication to upholding the highest standards as a UL Authorized Label Supplier underscores our commitment to quality. By understanding their significance and stringent requirements, manufacturers and consumers can better appreciate the value they bring to product safety and compliance. Contact us now, and let’s work together to ensure your next project meets all the requirements and criteria for an effective UL Label.