What are security labels and tamper-evident labels? As you all know, security is important. For this reason, tamper-evident labels and general security labels are used to deter counterfeiting. These also are used to confirm if a product is a genuine brand. Thanks to secured inventory management and controlled distribution services, security needs can control and ultimately achieved.

Tamper-Evident Labels

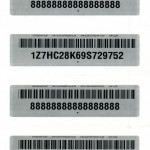

Tamper-evident security labels come in all shapes and sizes. Holograms, color change inks, micro text, consecutive numbered, and barcoded are just a few variations, including destructible labels. Also, before a security label is created for a product, one must determine what level of security is needed: low, medium, or high risk. The higher the risk, the more features the label must have.

Tamper-proof labels are also a form of security label sticker. They can be made from paper or film materials. The simplest form of tamper-proof is done with tooling or putting cuts in certain places, so once the label is applied to a surface and someone tries to remove it, the label is removed, the label will tear, and the warranty is void. Wikipedia explains the history, technologies, and industry needs of tamper-evident labeling.

Other designs include a visually apparent, fragmented residue which can indicate that the product’s security has been breached. This helps to eliminate the possibility of label switching. These labels can help with product warranty issues to prevent consumers from tampering with electronic equipment and any other product to which they are applied.

Different kinds of Security Labels & Tamper Proof Labels:

- Tamper-Cuts

- Tamper-Evident

- Destructible Material

- Holograms

- UV Indicator

- Void Patterns

- Micro Text

- Micro Taggants

- Permanent Label Masks

- Embedded Images

- Security Stickers

One of the more common tamper proof labels or security stickers includes Tamper-Evident Security Labels. These labels are designed by cutting edge manufacturers. They separate into layers when removed and add consecutive numbered barcodes to aid in the control of each part. Tamper-Evident Labels are extremely important in the packaging and labeling industry, simply because it is vital to know that the product has not been altered since it left the manufacturer.

Different ways to keep your products and packaging securely:

- Anti-Theft

- Evidence Tracking

- Original Product Verification

- Brand Protection

- Prevent Document Duplication

- Part Authenticity

- Parts Marking

- Tamper Evidence

- Counterfeit Deterrence

We here at Whitlam Group typically make tamper-proof labels out of films with the feature built into the adhesive layer. The label is applied to a surface. After a certain amount of time, the label is allowed to bond. At this point, if anyone was to remove the label the word “VOID” will show up on the film label and remain on the surface the label was applied to. These labels can be consecutively numbered, & barcoded.

For more information on Security Labels and Tamper Proof Labels please visit our Brand Security section.

One response to “Security Labels & Tamper Proof Stickers: The Basics”

Posted by Anthony Liebusch

Hello,

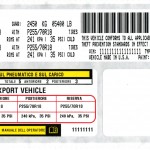

Can your company produce 4″ x 2.5″ sticker/labels that are tamper proof, durable, and adhesive to the inside of a vehicle windshield. They would need to withstand 12 months without the color fading. We require 9.1 million over a 6 year period. Each year a different sticker hologram background color is required.

The stickers will be embedded on a 8.5” x 5.5” laser printer compatible paper page. Our application would print the vehicle information on the center of sticker face, the user would then peel the backing of the sticker, which would expose the adhesive around the edge of the print area so that the sticker can be adhered to the inside of the windshield facing outward.

Thank you,

Anthony Liebusch

Posted on July 17, 2018 at 3:40 PM