The automotive industry has always been a space defined by innovation, and labeling technology has evolved right alongside it. As vehicles become smarter, more electric, and increasingly complex, labels must perform far beyond identification. Today’s automotive labels play a crucial role in ensuring safety, traceability, compliance, and optimal performance.

Whitlam Group has been at the forefront of these advancements, engineering labeling solutions designed to withstand the rigorous demands of both traditional and electric vehicles. Let’s explore how automotive labeling has evolved — and where it’s headed next.

1. From Identification to Intelligence

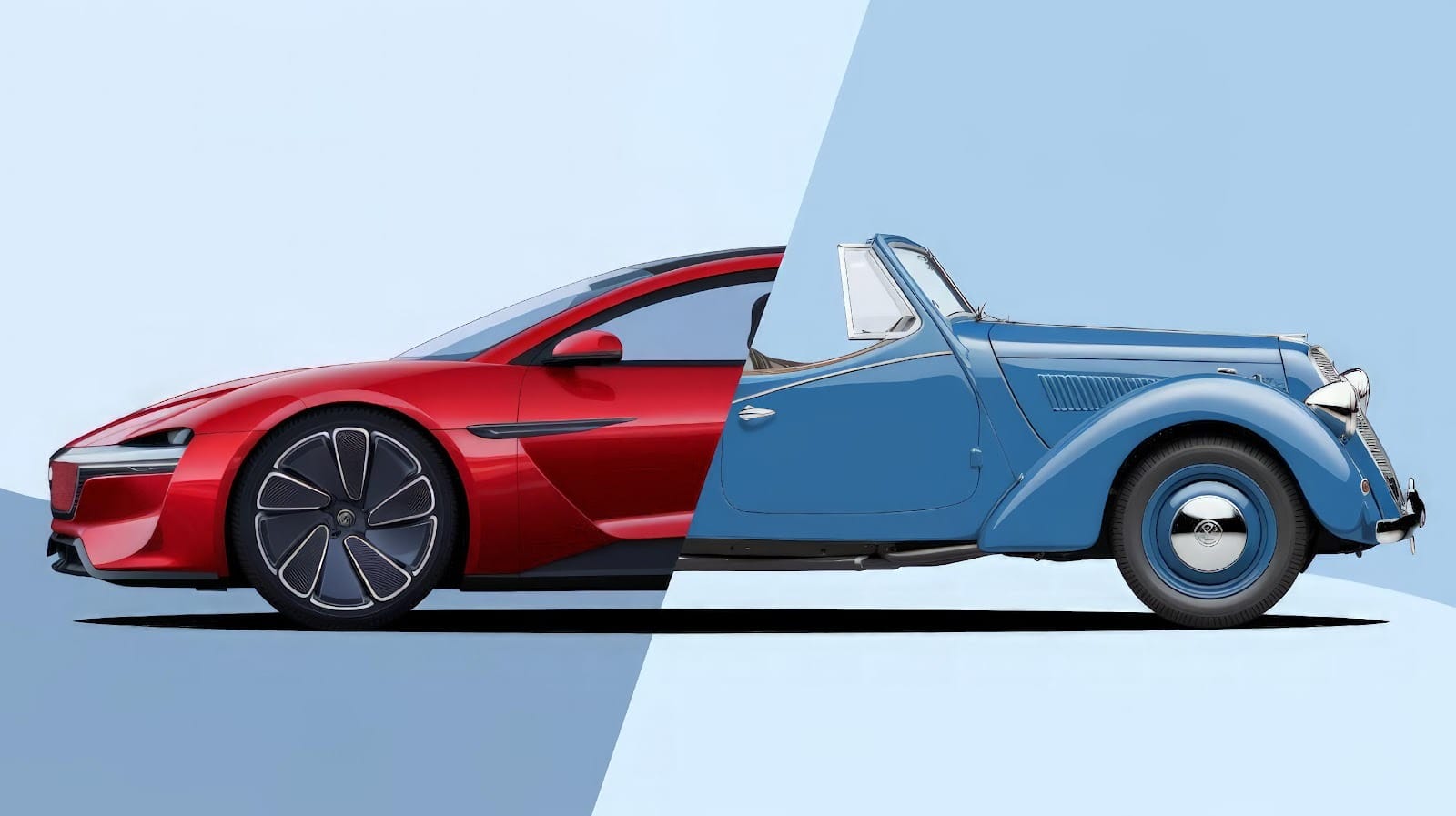

In the early days of automotive manufacturing, labels were simple — used primarily for basic identification. Over time, as vehicles integrated more electronic components, sensors, and data systems, labeling evolved into a crucial element of operational safety and compliance.

Today, labels do far more than display information. They provide traceability, enable digital connectivity, and meet specific regulatory standards from organizations like SAE, UL, and ISO.

2. The Shift Toward Electric Vehicles

The rise of electric vehicles (EVs) has accelerated the need for labeling innovations. EVs operate in different environments than traditional internal combustion engines, often exposing materials to higher voltages, extreme heat from battery packs, and chemical exposure from coolants and lubricants.

Whitlam’s materials are specifically tested and validated for these conditions — ensuring resistance to high-voltage environments, flame retardancy, and long-term adhesion across temperature fluctuations.

3. Compliance and Safety: Non-Negotiable Standards

Automotive labels aren’t just about branding — they’re about safety. Every part, from under-the-hood components to wiring harnesses, must be labeled for traceability, identification, and compliance. OEMs rely on label partners like Whitlam to ensure each material meets UL, PPAP, and performance validation requirements.

Our labeling constructions meet or exceed automotive OEM standards, ensuring that every product that leaves your facility remains compliant across its lifecycle.

4. Materials That Meet Modern Demands

The materials behind high-performance automotive labels are what set them apart. Whitlam’s engineered films and adhesives are formulated for:

- Extreme Temperature Resistance (–40°F to 300°F)

- Chemical and Fluid Durability (gasoline, oil, coolant, brake fluid)

- UV and Abrasion Protection for outdoor exposure

- Battery & Electrical Component Compatibility

These materials ensure performance whether applied on metal, plastic, or composite surfaces — even under the stress of vibration and heat cycles.

5. Labeling the Future of Mobility

As automotive manufacturing continues to evolve toward autonomous and connected vehicles, labeling will play an increasingly critical role in traceability and data management.

From RFID and QR-coded identification systems to tamper-evident safety markings, Whitlam continues to innovate solutions that support the connected future of mobility — where every label serves as both an identifier and a data point.

Work with Automotive Label Experts

The automotive industry is evolving — and so must labeling technology. Whitlam Group’s engineering expertise, rigorous testing, and commitment to quality ensure that every label is built for the future of mobility. Whether you’re producing combustion engines, hybrid systems, or fully electric vehicles, our labeling solutions are designed to perform under pressure.

Frequently Asked Questions

- How have labeling requirements changed with the rise of electric vehicles (EVs)?

Electric vehicles operate in high-voltage and high-heat environments, which place new demands on label materials. Modern EV labels must be flame-retardant, resistant to chemicals and coolants, and capable of maintaining adhesion on various surfaces, such as battery casings and power electronics. These durability standards ensure that safety and compliance information remains legible throughout the vehicle’s lifespan. - What materials are best for automotive labels in extreme environments?

High-performance automotive labels often utilize engineered films, heat-resistant adhesives, and protective coatings that can withstand temperatures ranging from –40°F to 300°F. They must also resist UV exposure, abrasion, and fluids such as oil, gasoline, and brake fluid. These advanced materials ensure long-term readability and compliance across both traditional and electric vehicle applications. - Why is compliance labeling so critical in the automotive industry?

Automotive compliance labeling enables manufacturers to meet UL, PPAP, and ISO standards, ensuring traceability, safety, and regulatory approval. Labels that meet these standards allow OEMs and suppliers to verify quality and maintain documentation for every part produced. Without compliance labeling, manufacturers risk failed audits, product recalls, and loss of OEM trust.