Label Error-Proofing – Preventing Costly Errors

History:

In the past, operators would pack and ship parts based on their visual characteristics. However, there was no error-proofing to prevent parts of similar color, shape, and size from being mixed up, so errors were often abundant.

Eventually, Part Number labels were added to prevent errors but visual discrimination was problematic for operators. For example:123456789 / 123465789. “Color Codes” were then added to Part Number labels for visual confirmation. Unfortunately, distractions, operator ability to see color variations, and work area environment factors often led to mistakes.

The weaknesses in “Color Codes” were clear so Barcode Labels, scanned by operators prior to packing, replaced them. This created a disruptance because “Color Coded” labels were a useful layer in the process for operators.

To fix the problem, a combination of Part Numbers, “Color Codes,” and Barcodes were printed on labels. Even with this system there were opportunities for errors because there was no integrated technology to prevent the same part with the same barcode from being scanned multiple times to satisfy the requirement.

Label Error-Proofing Advancements:

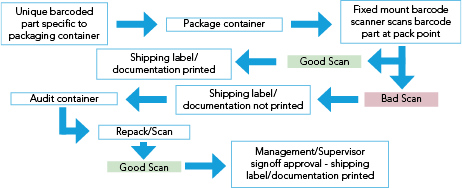

Labels have now evolved into a combination of best practices that include Unique Serialized Barcodes combined with integrated technology for error-proof scanning that prevents the next process if certain conditions are not met. For example, failed shipper if an incorrect quantity was packed or an audible/visual alarm if an incorrect barcode is scanned.

How to Error-Proof the Labeling Process

Integrated with the proper hardware/technology, Whitlam can provide a solution by utilizing part numbers clearly printed on the label, bright consistent colors and unique serialized barcodes applied to each part is a robust solution that prevents costly errors.

Error-proofing the labeling process is crucial for maintaining product integrity and avoiding costly mistakes. As a label maker, we recommend the following best practices:

Use High-Quality Materials: Select durable materials that can withstand various environmental conditions. This reduces the risk of labels deteriorating, ensuring they remain legible and intact.

Standardize Label Designs: Implement consistent design templates for similar products to minimize confusion and errors during production.

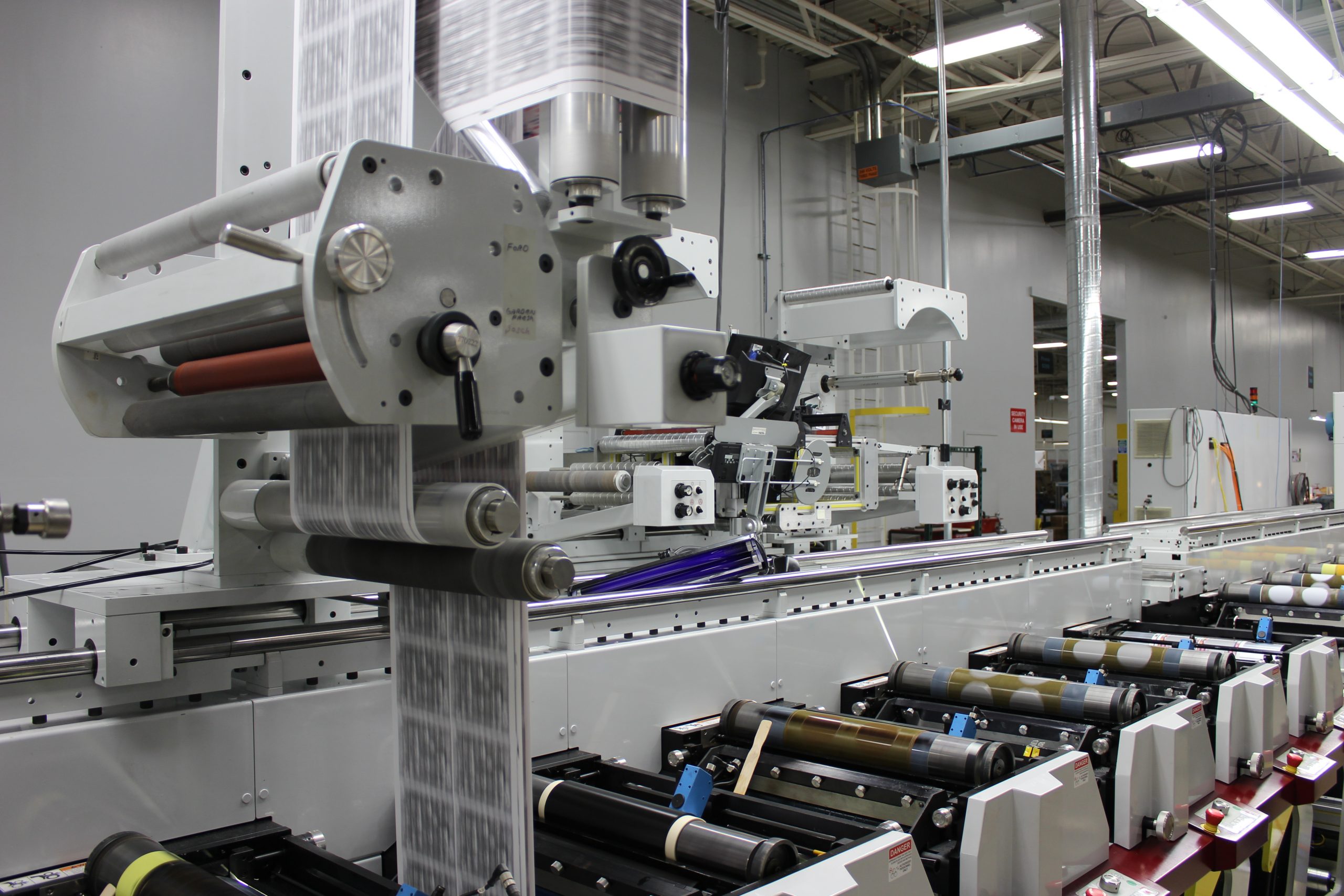

Automate Where Possible: Utilize automated labeling systems equipped with sensors and cameras to detect and correct misalignments or defects in real-time.

Conduct Regular Quality Checks: Perform routine inspections throughout the production process to catch errors early. This includes verifying barcode readability and label adhesion.

By following these practices, you can significantly reduce the likelihood of labeling errors and maintain label error-proofing standards.