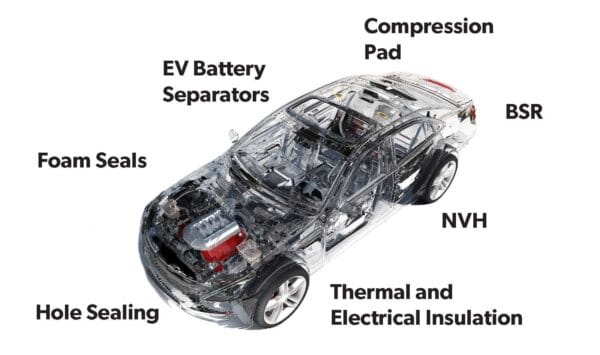

Whitlam manufactures parts that are used to assemble various sub-assemblies.

Whether the application is to reduce Buzz, Squeak, and Rattle (BSR), to eliminate Noise, Vibration, and Harshness (NVH), or to achieve light weighting goals to improve fuel economy we can provide an engineered solution.

Our team at Whitlam Group specializes in design, and custom converting to create a product to meet your needs. This could include solving a problem, providing efficiency gains, or reducing costs. Our state-of-the-art equipment allows Whitlam to accommodate some of the tightest tolerances in the industry, down to +/- 0.1mm (material dependent).

Our Servo-Motion control systems allow for island placement, and the ability to laminate many materials with great precision.

EV Battery Bonding

The use of pressure-sensitive tapes to bond pouch and/or prismatic cells together in EV Battery pack assemblies offer key benefits:

- Pressure-sensitive adhesives require no cure time, with immediate strength — they can act as an assembly aid and a bonding solution, unlike liquid applied products.

- There is no need for mixing nozzles or pot life concerns, as pressure-sensitive adhesives feature single-component functionality.

- Flame retardant and dielectric tapes are available when there are flame or electrical requirements.

To read more about Pressure-Sensitive Adhesive Automotive Bonding Applications click on the link to open our product brochure.