Whitlam group is an industry leader in complete engineered solutions for complex requirements. With over 50 years of experience in the automotive industry we have built relationships with many engineers and understand the complexity of OEM requirements.

Our custom-engineered solutions simplify the industry-making and manufacturing process, making them leaner and reducing costs. Whitlam’s goal is to make the tough stuff easy, and we are here to help you solve your high-performance labeling challenges with our engineered solutions.

Engineered Solutions For Label Manufacturing

- Application: Engineered for fast and easy label applications

- Extreme Durability – 5-10 year outdoor durability: UV exposure, extreme temperatures, protective overlaminates, aggressive and high-performance adhesives

- Specifications – We meet OEM and Industry specs: Outdoor power equipment, abrasion and chemical resistance, UL/CSA Certified

- Profile -Various application textures and profiles: Smooth textured, flat, compound curve, rigid, concave, convex, and recessed

- Surfaces – Various application surfaces include: Painted metal (deck hoods and engines), plastics (chutes, engines, and accessory parts), polypropylene, polyethylene, regrind, and mold release agents

- Resistance – Abrasion and chemical resistance: Product in-use, and exposure to gas, oil, brake fluid, water, grease, etc.

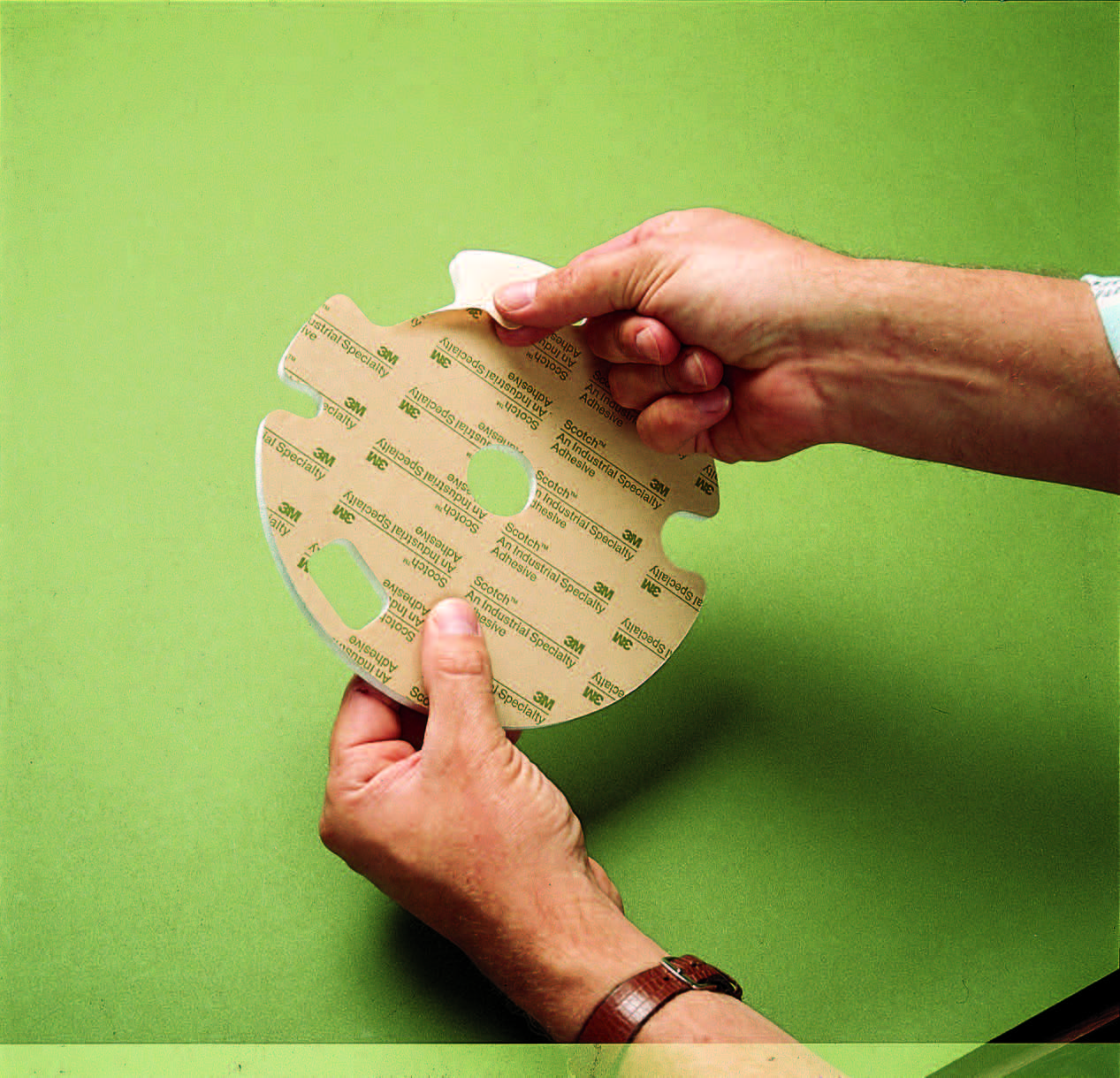

Custom Die-Cut Converting

Our team at Whitlam specializes in design and custom conversions to create a product that meets your needs. Our R&D team and highly-skilled engineers can help find the best solution for your application. One solution to replace mechanical fasteners during the application process is by using custom die-cut converting tapes. Some of Whitlam’s converted product solutions include:

- 3M™VHB™ Tapes

- Double-Sided Tapes

- Vinyl Tapes

- UHMW/PE Mylar Tapes

- PVC Foams

- Urethane Foams

- EPDM Foams

- Gaskets

- Bump, Squeak, Rattle

- Emblem and Decals

- Fuse Panel Labels

- Solutions for Galvanic Corrosion

- Custom Die-Cut Functional Labels

- And More

What Is Die-Cut Converting?

Die-cut converting is the process of precisely cutting labels into custom shapes and sizes using a die. In label manufacturing, it ensures accuracy, consistency, and efficiency, allowing labels to fit specific applications while enhancing branding, functionality, and ease of application. Our state-of-the-art equipment enables Whitlam to accommodate some of the tightest tolerances in the industry, down to ± .1mm (material dependent).

Harsh Environment Labels

Harsh environment labels have their own specific requirements custom to each customer. With a wide variety of materials and adhesives, Whitlam can custom engineer each solution to provide long-lasting performance under the harshest of conditions. Some harsh environment conditions include those related to temperature, abrasion, humidity, chemical, and UV exposure. Whitlam’s labeling solutions include:

- High-Temperature Resistant

- Chemical Resistant

- Paint Mask

- Direct Thermal Transfer

- Thermal Transfer

- Moisture Resistant

- Destructible

- Permit

- Barcode and Variable Content

- Extended Text and Booklets

- Channeled Adhesive

- And more

Product Identification and Part Marking

Product Identification is critical for Brand Owners, Design Engineers, Legal Departments, End Users, and many others. Gain control of your supply chain and let Whitlam custom design a solution for your products that need to be individually marked for Product Identification, Part Marking and Tracking purposes throughout the supply chain.

Functional Components

Functional die-cut component solutions are custom engineered to your specifications in order to improve assembly operations and reduce contamination, damage, and scrap all while generating cost savings. Some Functional Component products options include:

- Functional Die-Cut Components

- Protective Films-Covers / Masks

- Paint Mask

- Shatter Protection

- Electrical or Thermal Management

- Fastening

- Noise Control / Sound Dampening

- Double-Sided Adhesive parts for assembly or housing components

Whitlam Group can help you find the right label for your specific application that meets your specific requirements. Contact us today for more information!